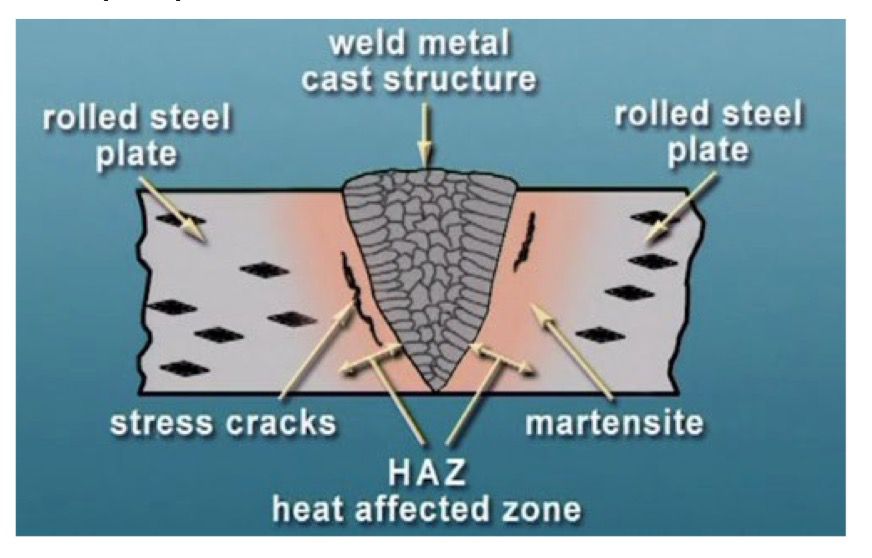

The Heat Affected Zone (HAZ)

During welding using a fusion welding process, there is a huge temperature difference between the weld and parent material. Because of this temperature difference, the material immediately adjacent to the weld undergoes microstructural changes. This area, which lies between the fusion boundary and the unaffected parent material, is called the heat affected zone (HAZ).

The extent of the changes in microstructure will depend on the following:

a. Material composition; especially carbon content.

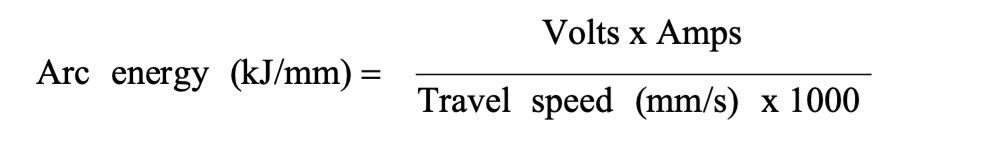

b. Heat input. The higher the heat input or arc energy, the wider the

heat affected zone. Metallurgical properties will also be affected.

Volts x Amps = Watts 1 V x 1A = 1 watt = 1 J/sec

c. The rate of cooling. The faster the rate of cooling the harder the heat affected zone, especially if the carbon equivalent of the steel is high.

The HAZ of a fusion weld on steel consists of up to four separate regions of microstructure, the actual condition will be dependent upon the alloying elements present and the thermal conditions applied during welding. The following grain structures – starting from the area immediately adjacent to the weld – are typically present on a 0.15% C steel:

- A coarse grained region (heated between 1100°C and melting point).

- A grain refined region (900 to 1100°C).

- A region of partial transformation (750 to 900°C).

- A region of spheroidization (just below 750°C).

On C-Mn and low alloy steels, the HAZ of the weld tends to be more brittle, i.e. it has a lower notch toughness, than the actual weld metal. The HAZ area is therefore more prone to cracking, especially when hydrogen is induced, although it must be noted that the tensile strength of the HAZ is normally high in comparison with the weld and parent material. Unfortunately, if a fusion welding process is being used, the heat affected zone cannot be eliminated, although it can be controlled using a properly applied welding procedure.